What’s an ARDUN? The Ultimate OHV Conversion for the Ford Flathead V-8

July 2020 • By Mike Herman, HandHFlatheads.comAs we learned in our flathead Ford V8 story here: www.torqtalk.com/home/ford-flathead-the-first-performance-v-8, the Ford V8 was not initially a performer. Out of the crate in 1932 the 221 ci produced only 65 bhp and even by the end of its life in 1953 the 239 ci ‘flattie’ only produced 110. Note: The ’53 255 ci Mercury did make 125 bhp—still no big deal.

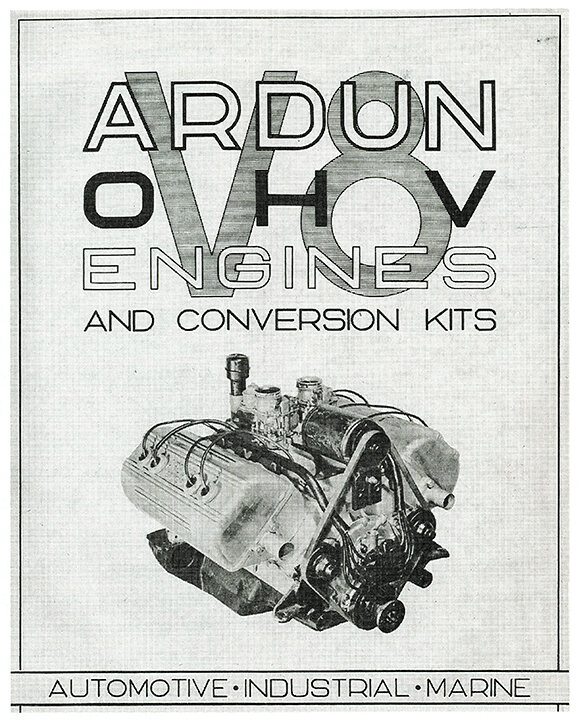

To make the Model A/B four bangers go faster several outfits had produced overhead valve (ohv) conversions it seemed obvious therefore to build something similar for the V-8. Enter brothers Zora and Yura Arkus-Duntov and the Ardun Mechanical Corp., New York. By 1945, their mainstay military contracts were dwindling and Zora approached Ford about an ohv conversion for the V-8 that over heated and was under powered. Ford showed no interest and so Zora went ahead anyway buying a couple of V-8s and designing his own heads with the help of engineer George Kudasch.

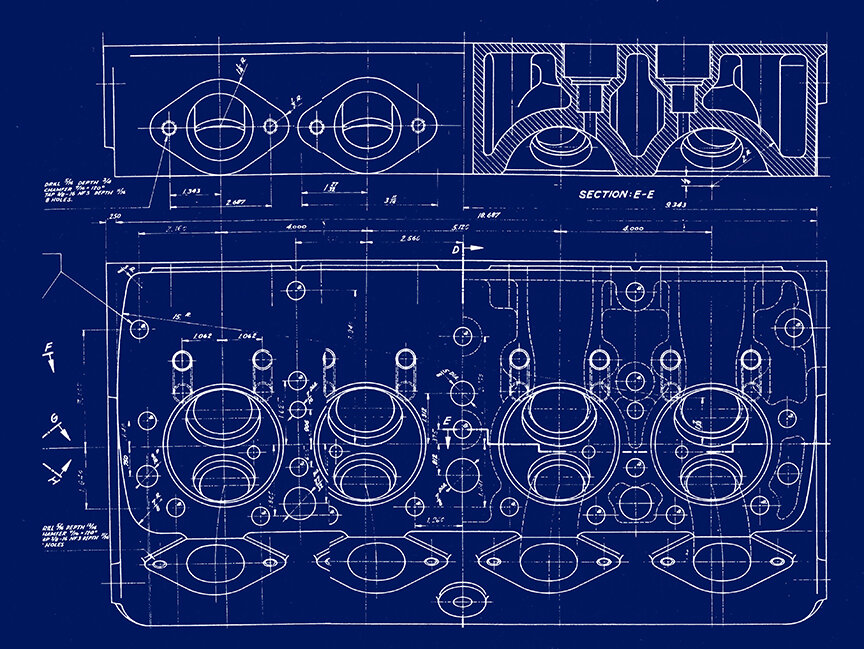

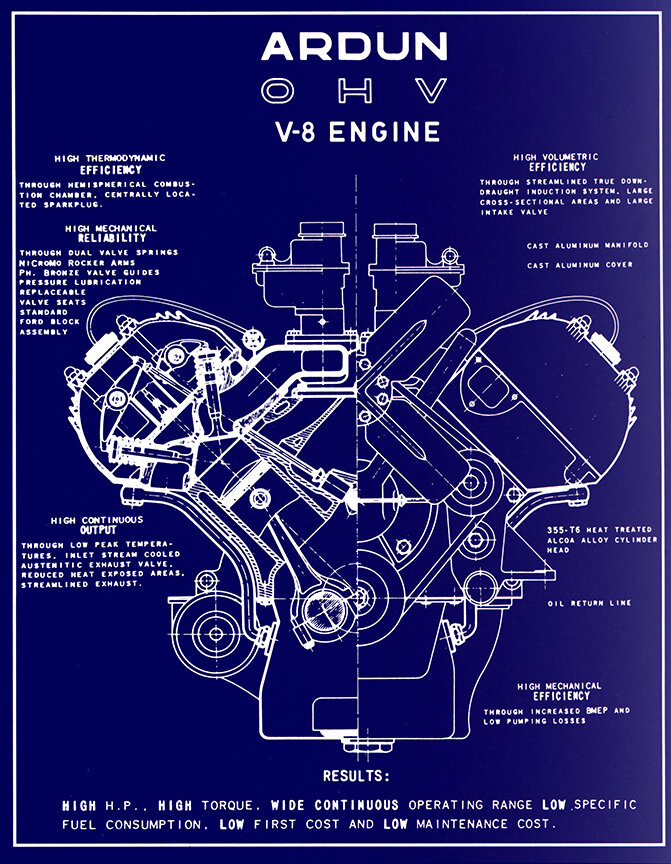

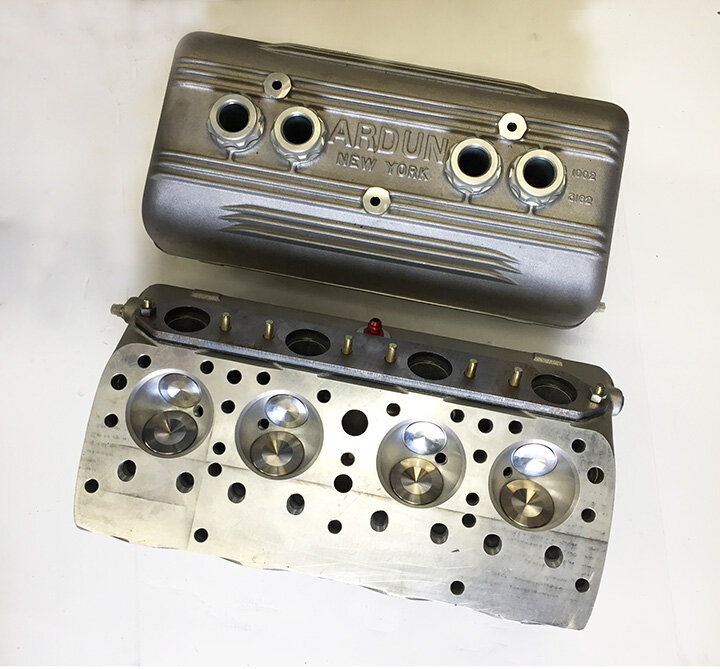

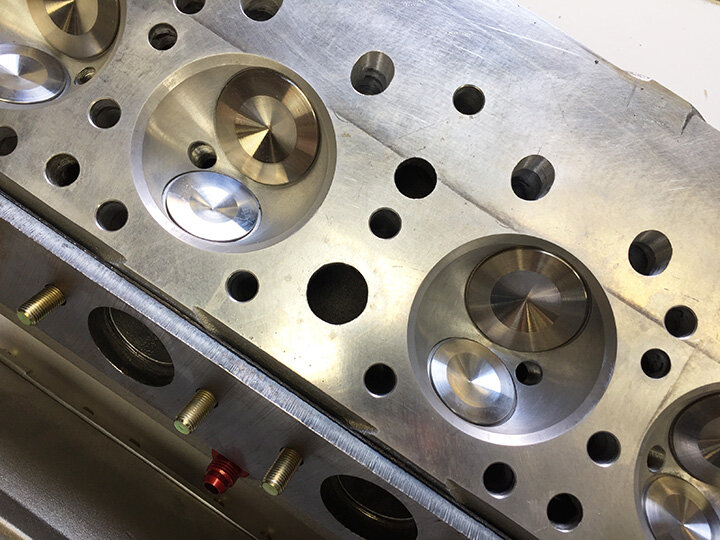

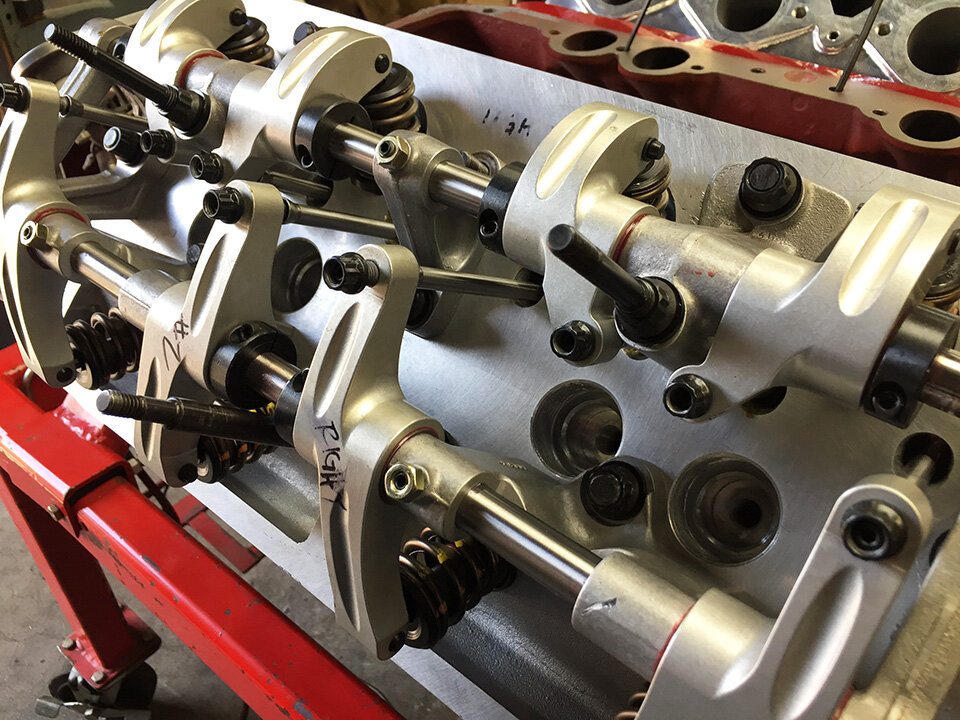

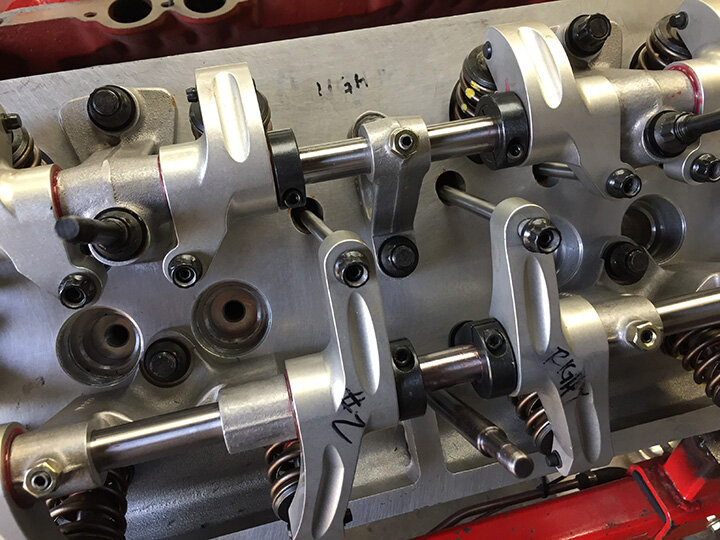

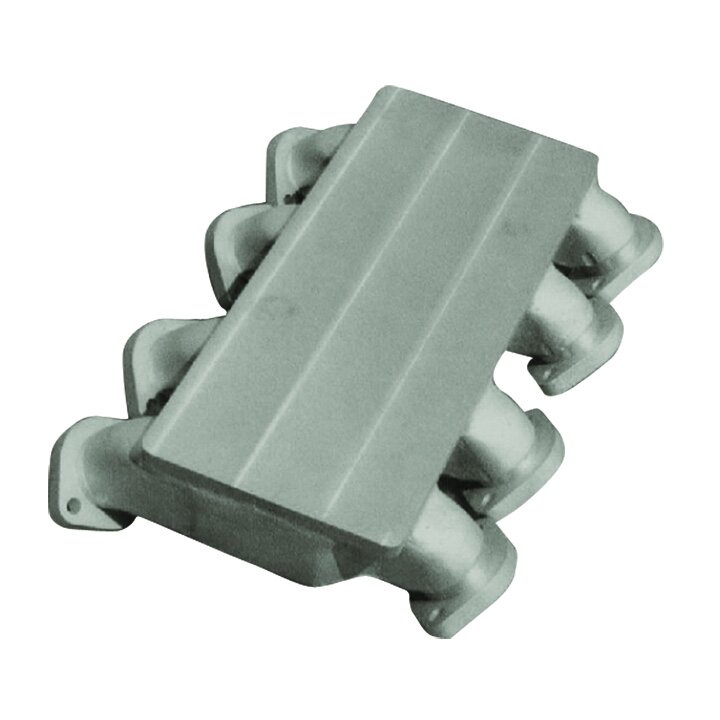

Rather than have the middle pair of exhaust ports asthmatically ‘siamesed’ into one, the Ardun, a contraction of ARkus-DUNtov, breathed better through four equally spaced ports. It was also compatible with the Ford block and valvetrain, used the stock cam, and had hemispherical combustion chambers and large intake valves for improved performance. Interestingly, the Ardun had short intake rockers and long exhaust rockers and was similar to the 1951 Chrysler Hemi but preceded it by four years when it was introduced in 1947.

The Ardun heads are 12-nches wider than a stock flathead Ford V-8 and consequently will not fit in most stock vehicles and they weigh at least 60 lbs.

The downside was trifold: The assembly was 12-inches wider than stock, it weighed an additional 60 lb and it wasn’t cheap being cast from heat-treated, 355-T6 Alcoa aluminum alloy. However, the heads produced between 25- and 60-percent more power depending on tuning—the original had but a single carb. According to Zora, “I had about 230 hp on gasoline by 1949.”

Zora might have been a tad optimistic with his figures. After almost two years and more than 1,000 hours of testing on his own GE dyno, the Ardun-headed engine put out only 160 bhp. ‘Build it and they will come’ was Zora’s philosophy and he attempted to market complete engines and conversions. A ‘racing’ version was said to produce 200 bhp at 5,500 rpm. The conversion sold for a hefty $500 and installation took six skilled hours. Two thousand inquiries resulted from a feature in Popular Mechanics but few sales materialized.

Zora attempted to market the Ardun with a small four-page brochure but it was too little, too late and orders failed to materialize.

The truck market appeared lucrative and a New York Times article on August 18, 1947, extolled the virtues but again there were few orders. It was too little, too late, too complicated and too costly and only about 200-250 sets were made. Despite minor success with an Ardun V-8-60, Zora lost the Ardun Company but he and Yura retained the name.

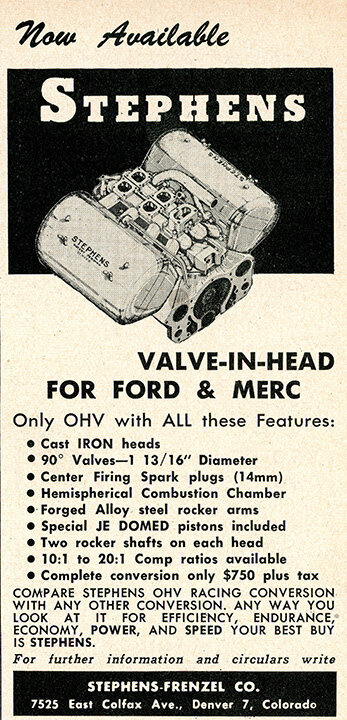

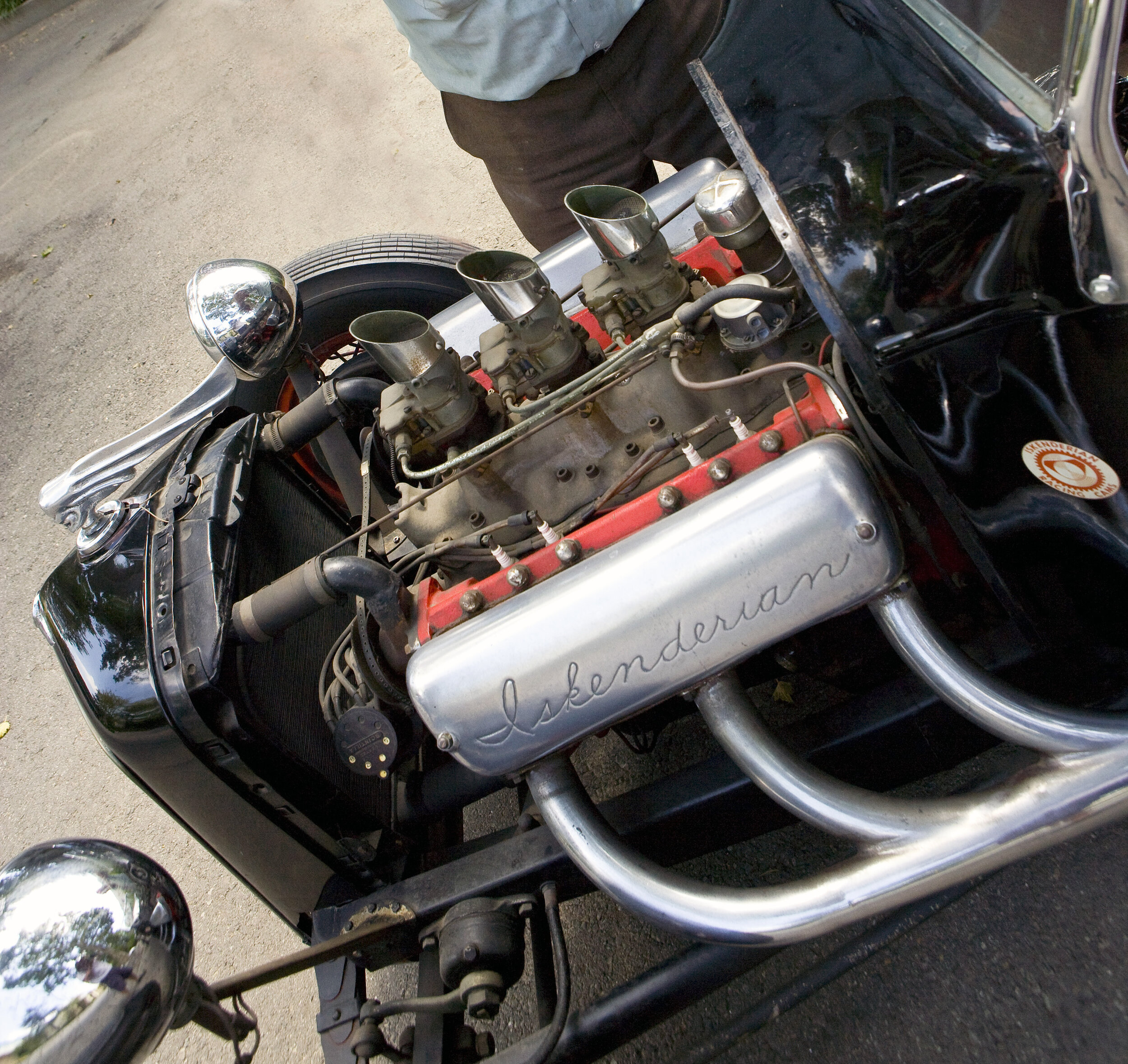

There were several other ohv conversions including Alexander, AJBirner, Cummings, Riley and Stephens but none were made in the quantities of the Ardun. The Maxi heads shown above right were used by Ed Iskenderian in his infamous T.

According to D. Randy Riggs writing in Automobile Quarterly, “Its cast steel push rods were too heavy as were the valves, and the seats came loose. The Buick-derived lifters tended to gall, the valve springs were inadequate, the exhaust manifolds were restrictive and head gaskets were a common failure. Ray Brock of HOT ROD called it, “A great hot water heater.”

Don Clark and Clem Tebow of C.T. Automotive resolved many of the Ardun’s flaws and ran over 160 mph at Bonneville in 1951.

Despite Brock’s bashing, Don Clark and Clem Tebow of C.T. Automotive, Sherman Oaks, CA, worked out the Ardun’s shortcomings and according to D. Randy Riggs, “switched to Chrysler valves, changed valve spring pressure, used tubular push rods, aftermarket cams, (some with roller lifters) and replaced the fiber cam gear with an aluminum gear. They also built their own sliding-valve injection system and equal-length headers.

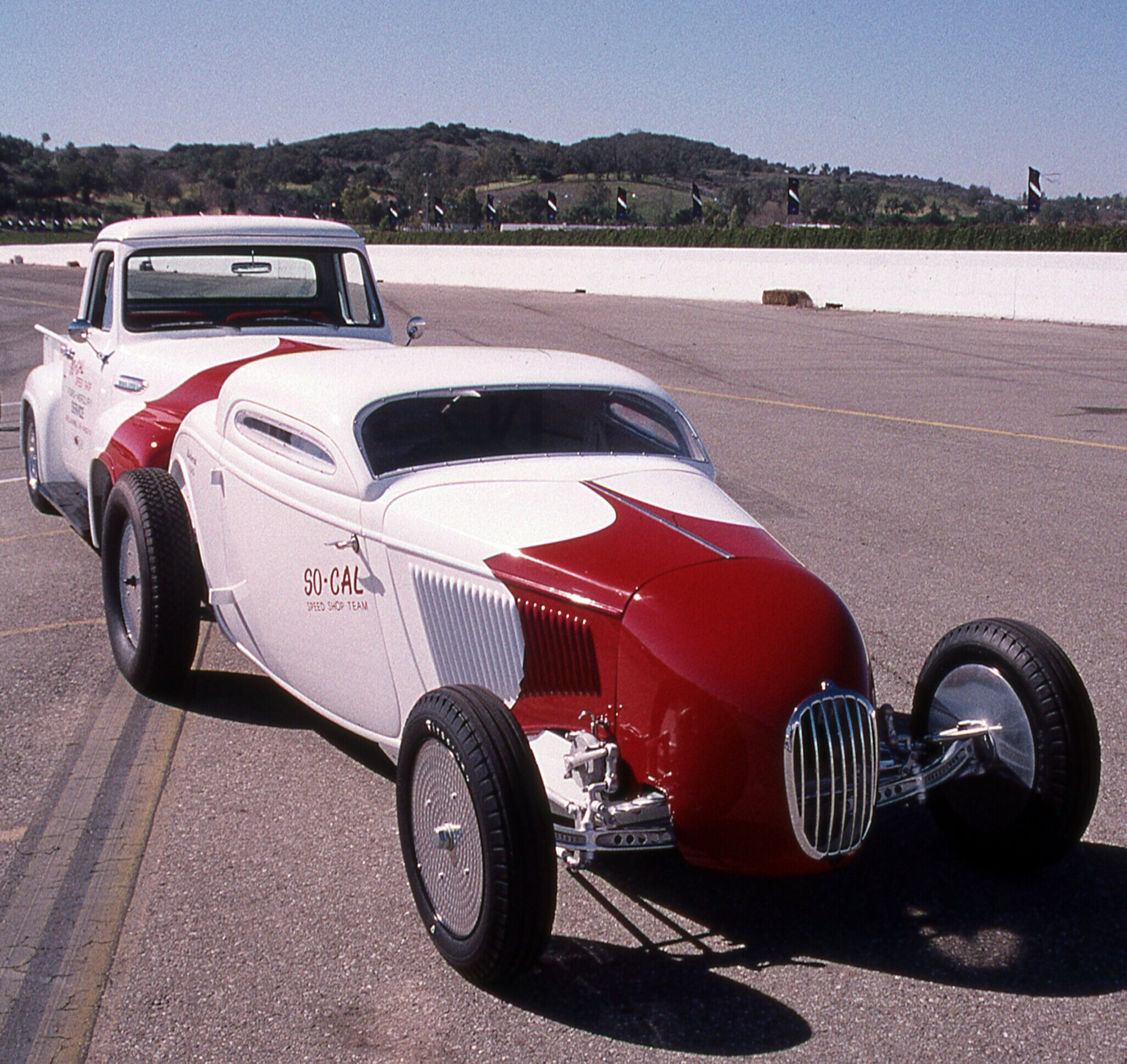

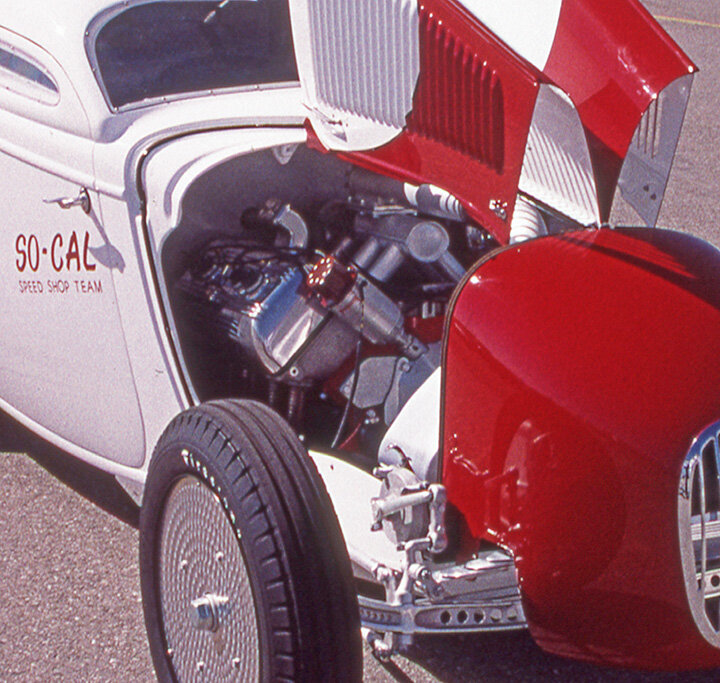

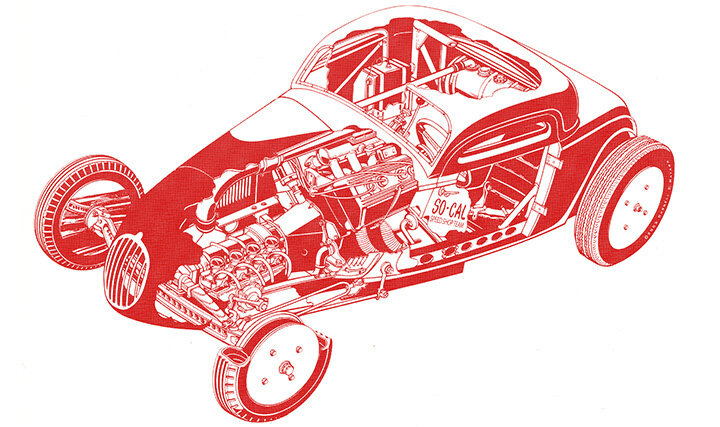

Ardun powered, C-T’s 284 ci ’32 Roadster averaged 162 mph at Bonneville in 1951. In 1952, a similar engine was installed in the Hill & Davis’ ‘City of Burbank’ streamliner and set a flying mile record of 229.77 mph. The following year, Charlie Scott drove the Scotty’s Muffler Service belly tank and became the first to top 200 mph in an open-wheeled car with a speed of 201 mph. Perhaps one of the most famous proponents of the Ardun was Alex Xydias’ SO-CAL Speed Shop Coupe that raced Bonneville and the drags with a front-blown Ardun. As Zora had hoped, the Ardun was king but only for a day as the GM overheads and Chrysler Hemis were about to dethrone it.

Zora had aspirations to be a racing driver and convinced British sports car maker Sydney Allard that the Ardun was the answer to the Allard’s power needs. Consequently, an Ardun went to England and an Allard J2 was shipped to New York where Zora dropped in another engine fitted with three methanol fed carbs. He raced at Watkins Glenn on September 17, 1949, but was black-flagged. Nevertheless, the Allard-Ardun showed great promise.

Knock-down Ardun kits were shipped to England where Sydney Allard assembled them as Made in England with a small brass plaque where it previously said New York.

After the race, Zora went to England and convinced Allard to hire him. Post-war import restrictions necessitated shipping knock-down engines to be assembled in England at A.E.C. and Monaco Engineering. Allard was the sole customer of Arduns ‘Made in England’ and a small brass plaque replaced the cast-in words New York. Eventually Allard took over all manufacturing and distribution rights. Zora retained a royalty for every pair sold.

While Zora returned to the US to work for General Motors his namesake continued to suffer its inadequacies and in the early to mid-fifties was eclipsed by numerous ohv engines, in particular the small-block Chevy that Zora eventually had a hand in developing.

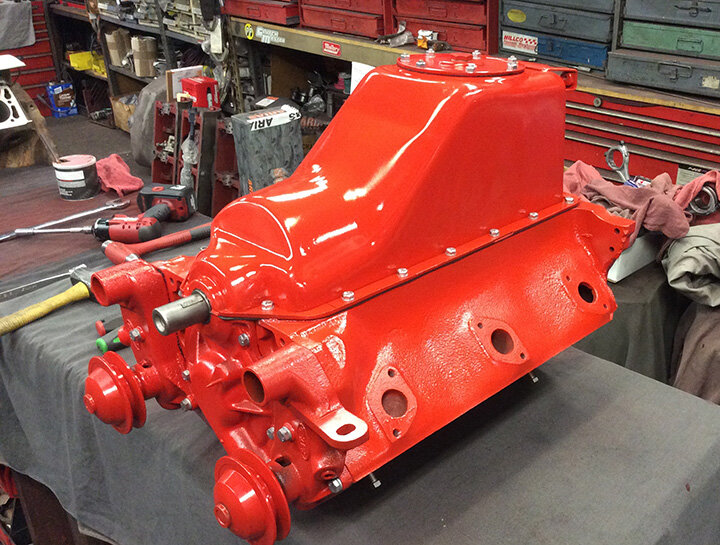

Despite its shortcomings the Ardun remained the Holy Grail of hot rod engines and consequently the late Don Orosco of Monterey Speed & Sport put the heads back into production. Don resolved many of the Ardun’s inadequacies, apparently made about 30 sets and even used a pair in his restoration of the SO-CAL Coupe that went on to win its class at the Pebble Beach Concours d’Elagance.

While they might appear expensive, there’s a lot of engineering, a lot of components and a lot of machining in a pair of Ardun heads.

Eventually, Don passed the project on to Don Ferguson who continues to produce the heads further updated with modern technology. He also makes a compatible cast-aluminum block.

The only drawback with the Ardun heads is cost. They’re made in USA, complicated and produced in small numbers and that is reflected in the price of approximately $15,000/pair. Five different intakes are available including 2x2s, 3x2s, 4x2s, a 4 bbl and a blower and they cost $1,000 each. Cast aluminum Italmecannica oil pans are around $1,400. A matching S.Co.T. blower is another $8,000 and if you want the whole caboodle polished sit down and add a few more thousand.

Is it worth it? Of course, no engine is perhaps quite as stunning as a fully polished Ardun especially when fitted with one of the Italmeccanica oil pans and a S.Co.T. blower. But you don’t have to polish it. Plenty of builders such as Andy Leach of CalAutoCreations.com have tried different finishes such as that found on the ’30 Coupe he built for Wayne Carini of TV’s Chasing Classic Cars (lead photo). If you want the baddest looking and sounding flathead on the block go with an Ardun.

For more information visit: HandHFlatheads.com