S.Co.T. The Ultimate Vintage Hot Rod Supercharger

November 2020 • By Tony Thacker, thanks to Jay Fitzhugh and The Rodder's Journal

Presented by HandHFlatheads.comY’all know what a Jimmy is right? In our world, Jimmy is slang for a GMC supercharger typically similar to what you see atop a V-8 engine. American brothers and inventors Francis Marion and Philander Roots invented the Roots-type supercharger, of which the Jimmy is one, in 1860. They developed what is known as a positive-displacement pump to move air in industrial applications.

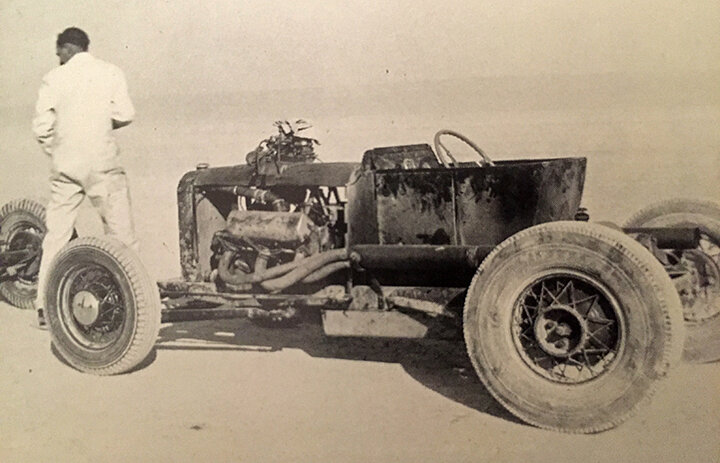

The first recorded use of a supercharger on a racecar was by Mercedes in the Coppa Florio race in 1921. The first recorded use of one on a hot rod was by Bill and Tom Spalding who fitted a Mercedes unit to a Riley ohv Ford V-8 in 1938. With a homemade intake and two Stromberg carbs, the Spaulding’s Modified ran about 120mph. The supercharger apparently cost $100 from a foreign car wrecking yard in Los Angles. It possibly came from a Mercedes 500K (K for kompressor) that had been introduced in 1934 at the Berlin Motor Show.

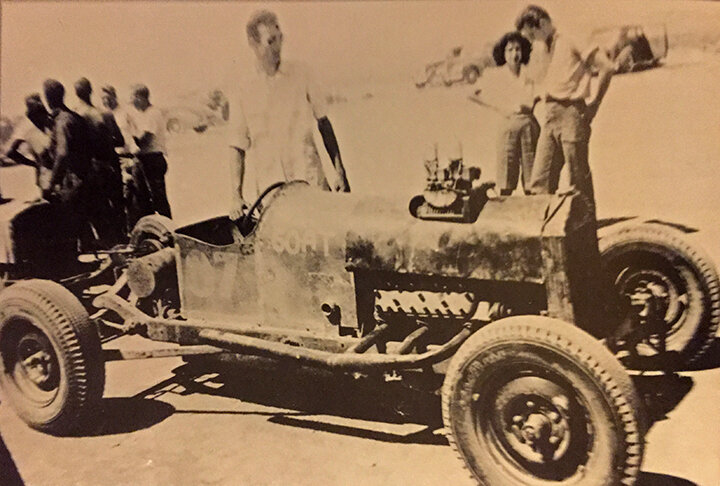

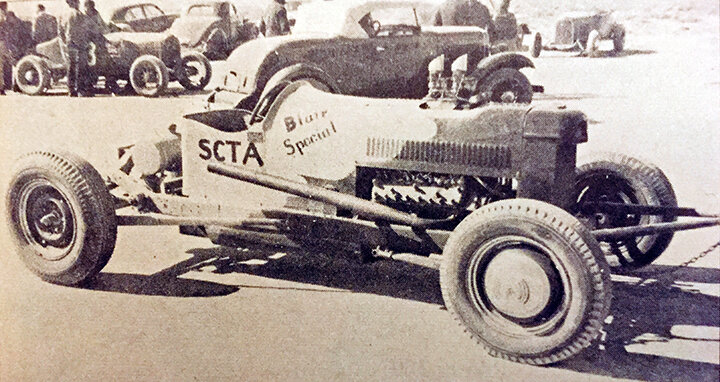

When the Spaldings moved on to race a streamliner, they sold the hot rod to Howard McKessen, meanwhile, Don Blair put a Mercedes blower on top of his Modified and it might have been the same blower. Either way, with a ’46 Merc’ engine, Denver heads, a Weiand intake and a Harman cam Don managed 141mph in 1946.

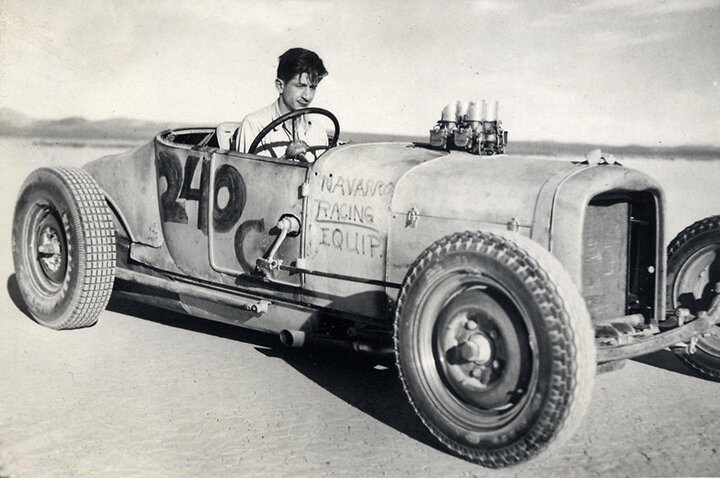

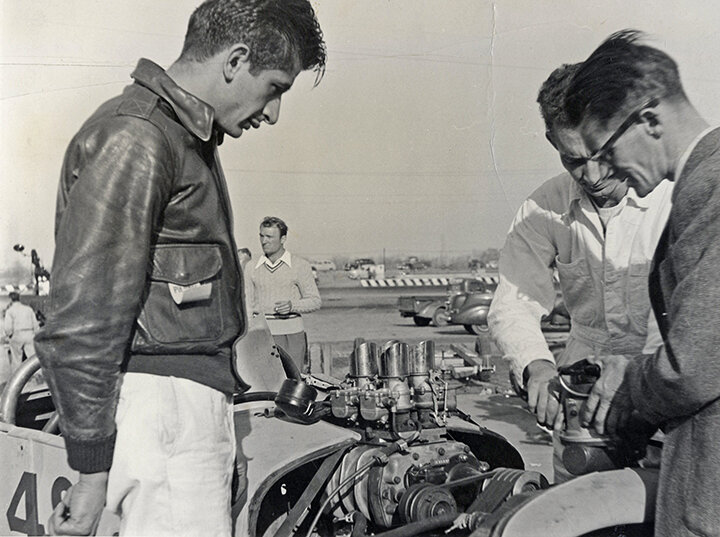

By then, however, American hot rodders such as ‘Kong’ Jackson and Barney Navarro had discovered the homegrown GMC ‘Jimmy’ blower developed for diesel engines in the late-thirties. Kong had shown up at the lakes in 1948 with 3-71 salvaged from a landing craft and subsequently sold it to Navarro for $60. Navarro quickly re-engineered one of his intakes and he was off to the races, quickly followed by his employee Tom Beatty who tried a larger 4-71.

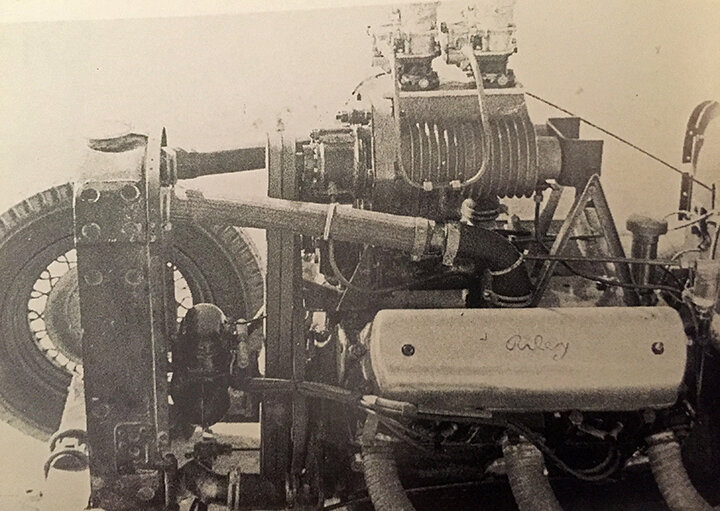

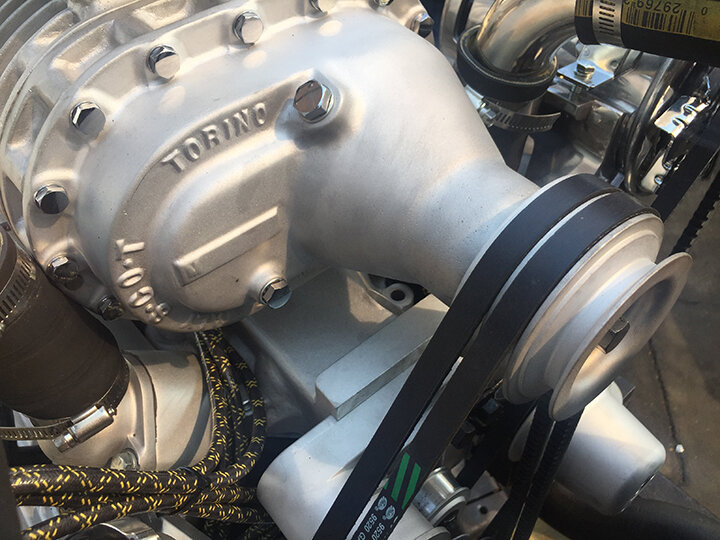

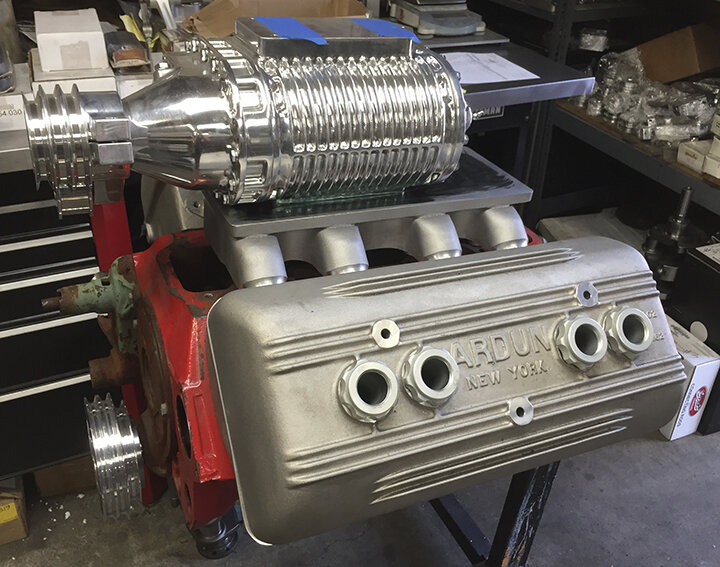

An original Italmeccanica atop a flathead Ford V-8 with Elco twin-plug heads being assembled at H&H Flatheads.

Meanwhile, in Post-War Europe countries such as Italy were trying to get back to work but materials and markets were in short supply, Nevertheless, in Turin (Torino) circa 1950 the Italmeccanica Co. (IT) was formed to build automobiles powered by supercharged Ford V-8 engines. The car was a failure but the blower was somewhat more successful.

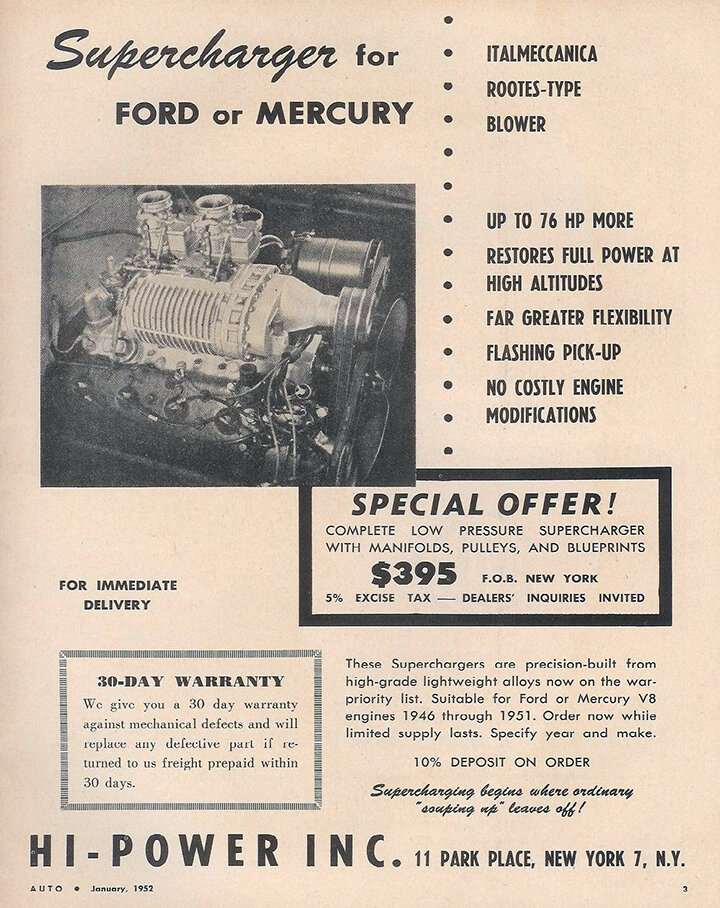

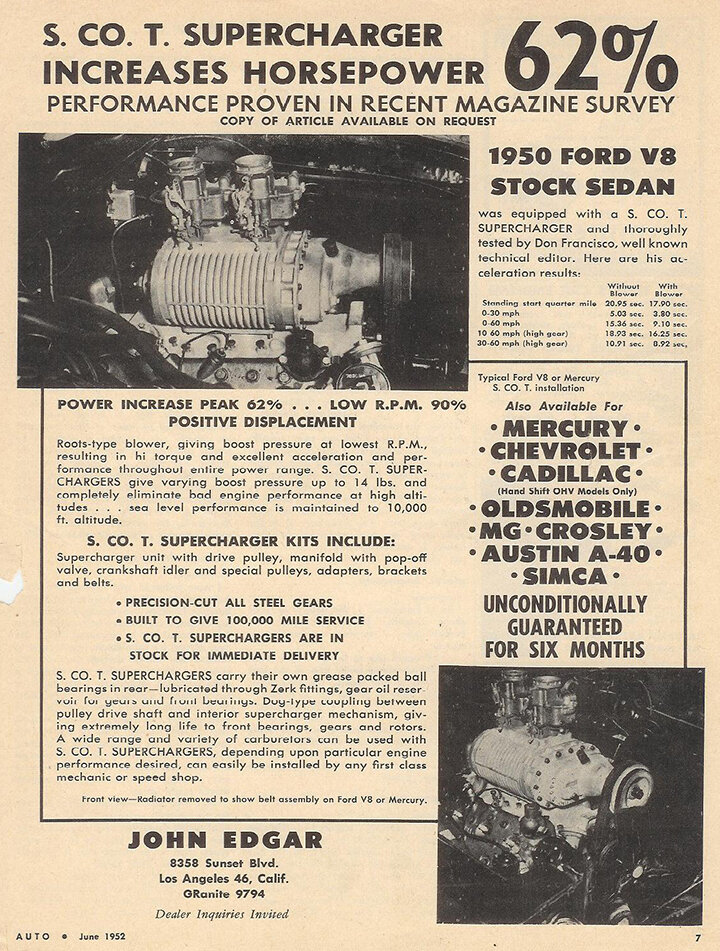

According to Jay Fitzhugh, writing in The Rodder’s Journal #29, IT produced nine different blowers with capacities ranging from 500cc to 4000cc for the Ford/Mercury. Supercharger kits were imported by Italmeccanica, New York, and distributed by Antonio Pompeo of Hi-Power in New York and John Edgar in Los Angeles. In 1952, hot rodder and sports car racer Ernie McAfee was also advertising the S.Co.T.

Hi-Power eventually dumped the Italmeccanica kits for just $85

Unfortunately, those early IT kits were made of poor materials, were held together by an odd assortment of mismatched European fasteners and had crude instructions. Consequently, IT was dissolved only to re-emerge as Societa Compressori Torino. In due course they announced a new and improved blower to be marketed as ‘S.Co.T.’ The problem was tons of inferior IT blowers dumped on the U.S. market for as little as $262.50 with a second carb thrown in for free. Eventually, Hi-Power of New York dumped their remaining Ford kits for $85. The new S.Co.T. sold for $424.50.

All this was playing out as Detroit was introducing new ohv engines that were more powerful that the aging flathead Ford even when blown. The S.Co.T. was cool but it was too little, too late and it was overshadowed by Jimmy-blown ohv V-8s. However, it remained a rare and desirable piece of vintage speed equipment.

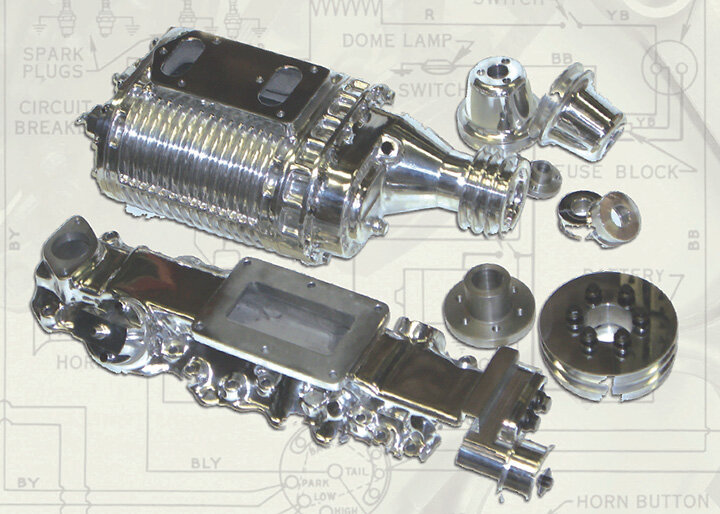

Mike Herman worked with father Max to develop a brand new, Made in USA S.Co.T. supercharger faithful to the design of the original but with brand new, up-to-date internals and manufacturing processes.

In 1972, Max Herman formed H&H Antique primarily to rebuild early Ford 4-cylinder and V-8 engines for the restoration market. In 2003, his youngest son, Mike, split off the V-8 business to form H&H Flatheads, however, the family continues to work together out of the original La Crescenta, CA, facility and in 2006 developed a new and improved S.Co.T. that is entirely Made in USA.

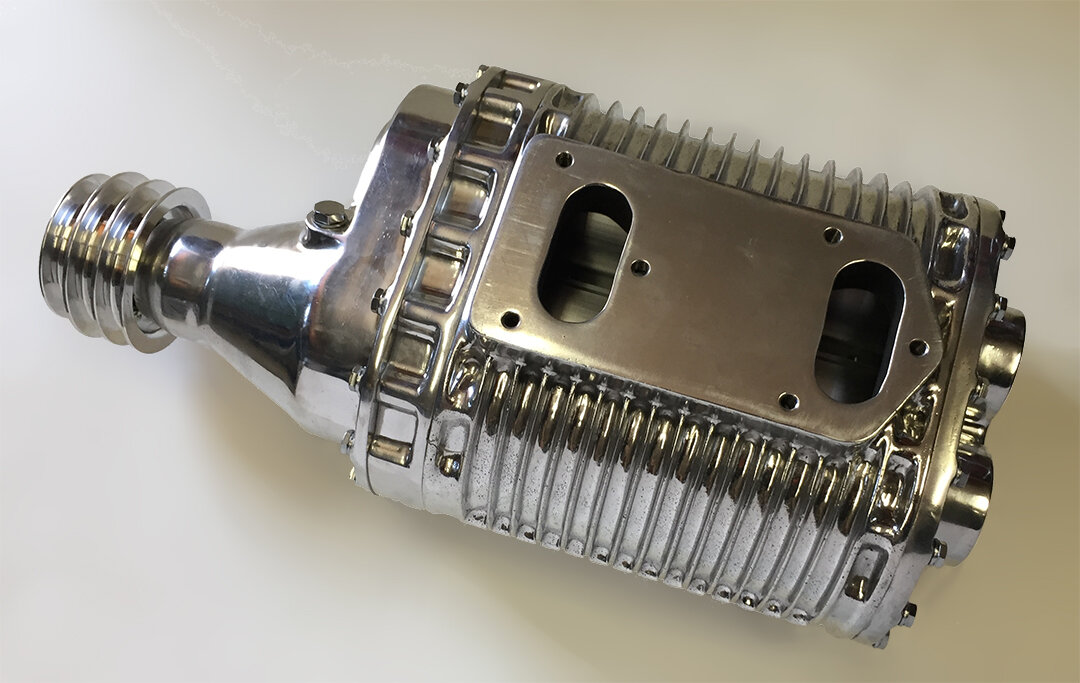

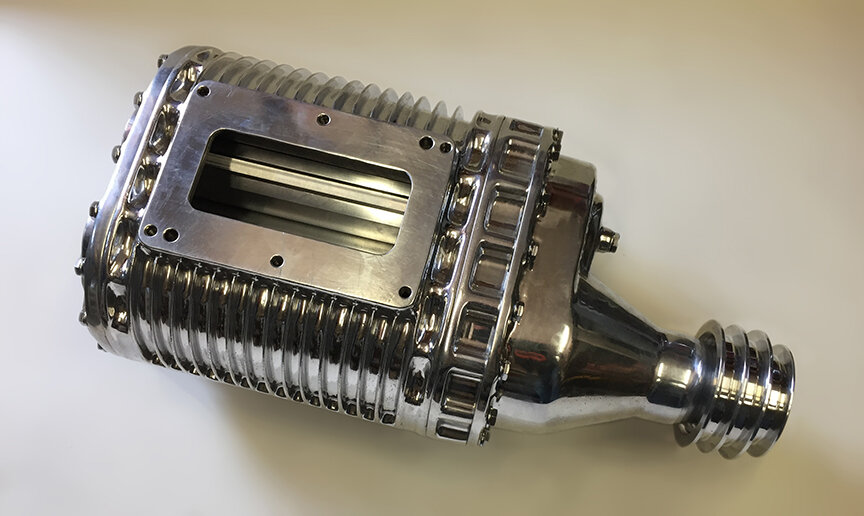

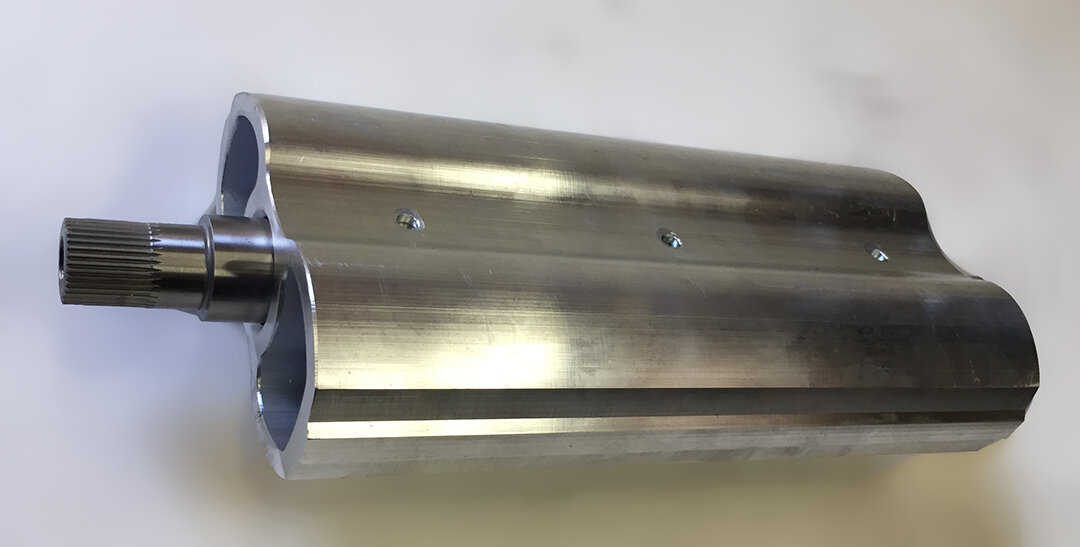

H&H began by developing a brand new case that has none of the porosity of the originals. The case is cast in Los Angeles from 356 aluminum, heat treated to T-6 and then precision machined to accept brand new two-blade, parallel rotors made from extruded billet aluminum—the originals were cast. The rotors are also CNC machined for exact and repeatable tolerances—something that could not be said of the originals.

The early blowers suffered several problems one of which was a one-piece drive shaft from the drive pulley all the way through the rotor to the rear-bearing cup. According to Fitzhugh, “This single shaft was subject to twisting under acceleration, which then could cause the rotors to scrape and wear against each other.” The H&H driveshaft is two-piece and rather than the original tapered and keyed fitting for the drive gears has a fully splined shaft with bolt-on gears.

The gears themselves are likewise superior in that they are precision-cut; high-grade steel with internal splines and precision cut helical teeth. The early IT blowers had straight-cut gears made of soft material. According to Fitzhugh, “The gears deteriorated under stress, and when a tooth broke, it could literally split open the case as the gears were forced apart.”

The H&H end plates, like the case, have been re-designed for increased support of the rotor shafts and the bearings, which are new, permanently lubricated, sealed C3 roller bearings that are through-bolted to their shafts. Incidentally, the rear plate has screw-in bearing retainers and fake grease fittings to retain that vintage appearance.

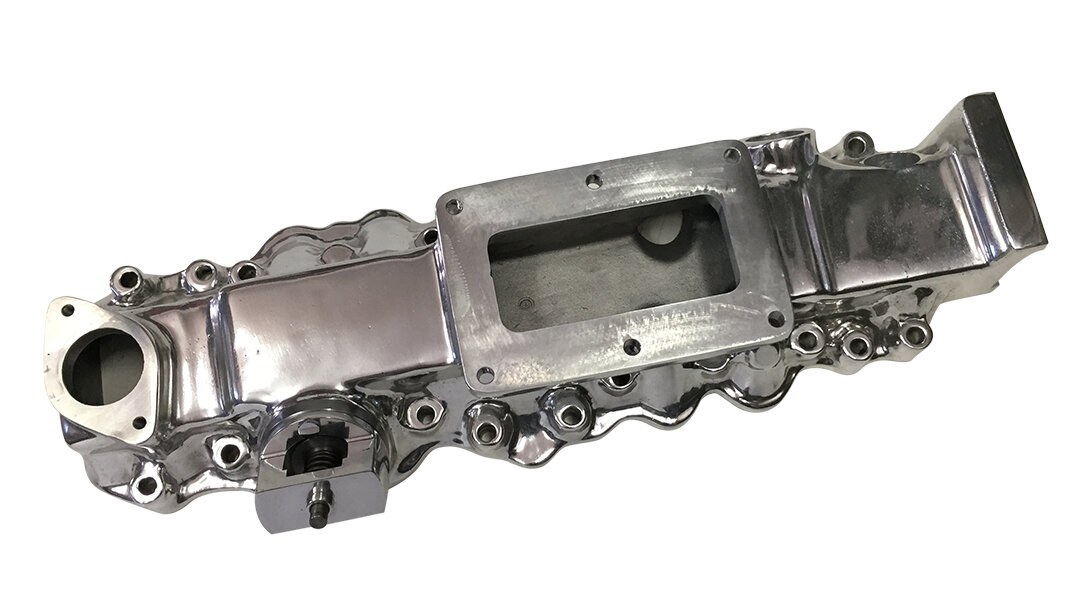

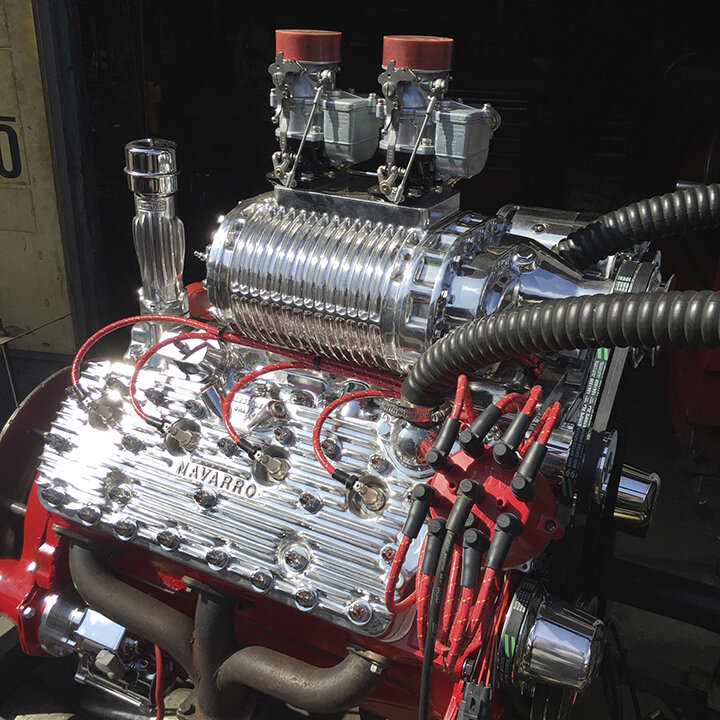

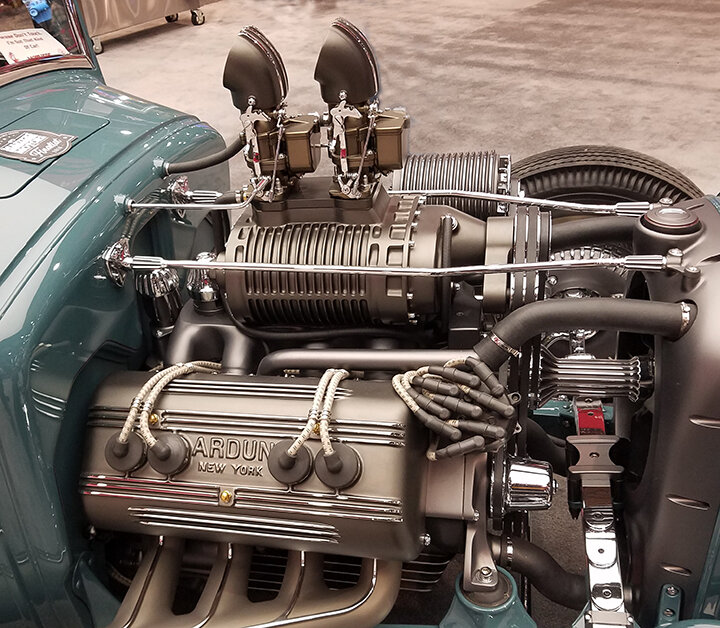

The H&H S.Co.T. supercharger assembly polishes beautifully and is designed to bolt to a similarly re-engineered intake based on the S.Co.T. original fitted with a mechanical pop-off valve. The blowers accept a pair of Stromberg 97 carbs. The kit comes complete with a crank pulley; tensioner and new matching aluminum water pump pulleys. Polished or unpolished the new H&H S.Co.T. looks fantastic atop a flathead Ford V-8 or any other vintage engine.

For further info contact HandHFlatheads.com