Bob Matranga’s 800 hp 540 ci Twin-Turbo Merlin-Based ’55 Chevy ‘Brute Force’—Part 2: The Car

March 2021 • Photos by Nestor Cabrera, Tony Thacker. Eric Geisert and Scott Council photos courtesy Bob Matranga

Presented by MicksPaint.com & USAutomotive.co.ukMost cars are a year or two in build, some take a year or three, and then there are those that take a decade or more. Not for any particular reason, it’s just that sometimes that’s how it goes. Bob Matranga’s ’55 Chevy ‘Brute Force’ is one that took a little longer than Bob originally anticipated but then Bob is particular about his builds.

Some projects get off to a shaky start and that’s, unfortunately, what happened to Bob’s Chevy when a shop that we won’t name drooped the front fenders— but not the same both sides. They also chopped the top but cockeyed t’other way. It was enough to make any man cry, but Bob was determined to see through what resulted in a 10-year build.

Chris Brown, the designer of ‘Brute Force’ said: “We tried to push the envelope with this car. When you’re trying to create something that has a lot of hand-made components it’s hard to make it perfect and it’s that challenge that makes these cars so special.” A walk around Brute Force reveals detail upon detail that just blows the mind.

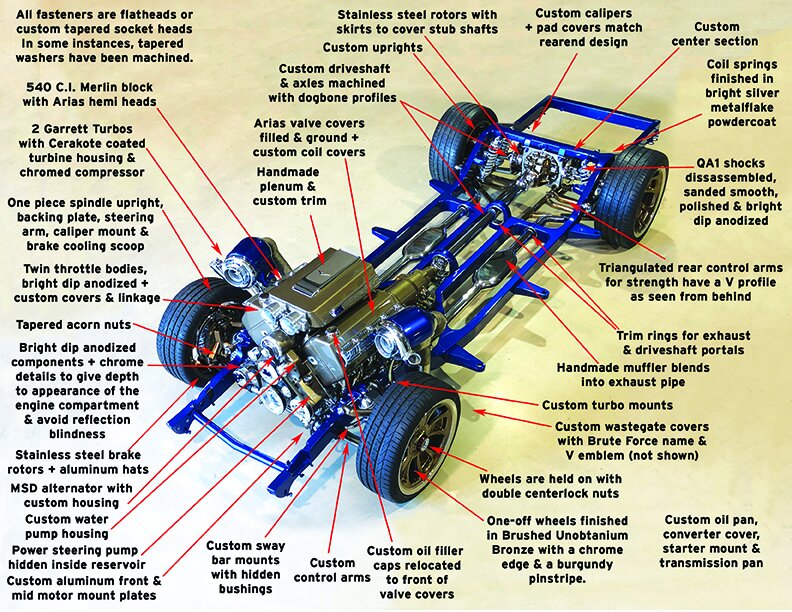

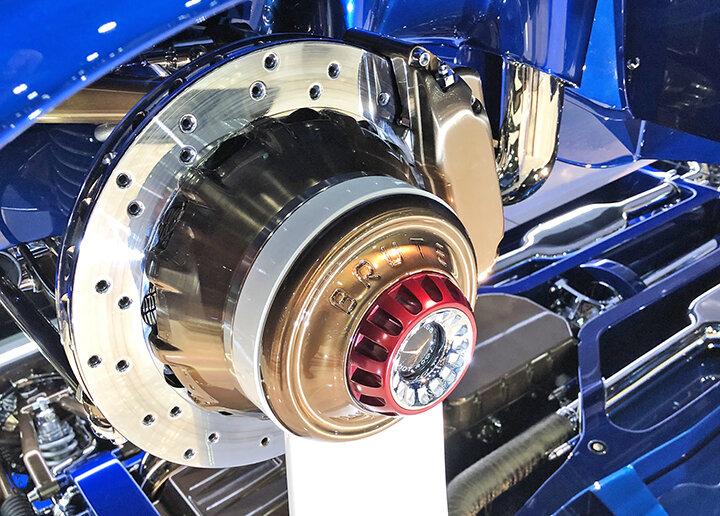

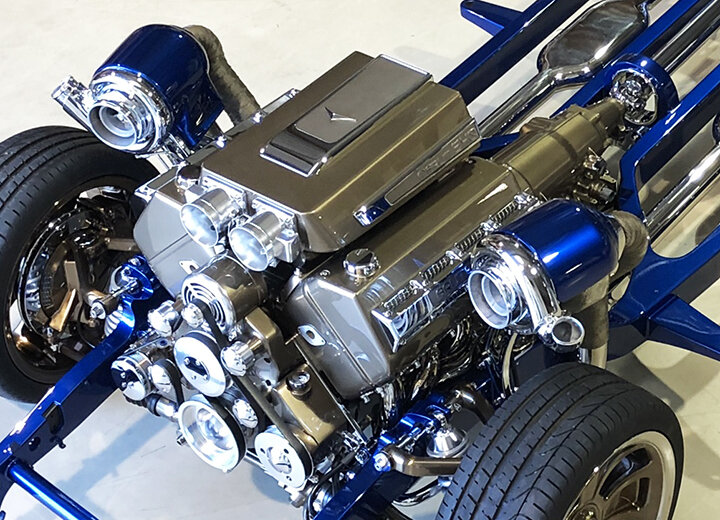

Brute Force rides on an Art Morrison frame fitted with Kugel Komponents’ independent front and rear suspension with QA1 shocks. The brake rotors and drive shafts are from Jennison Engineering.

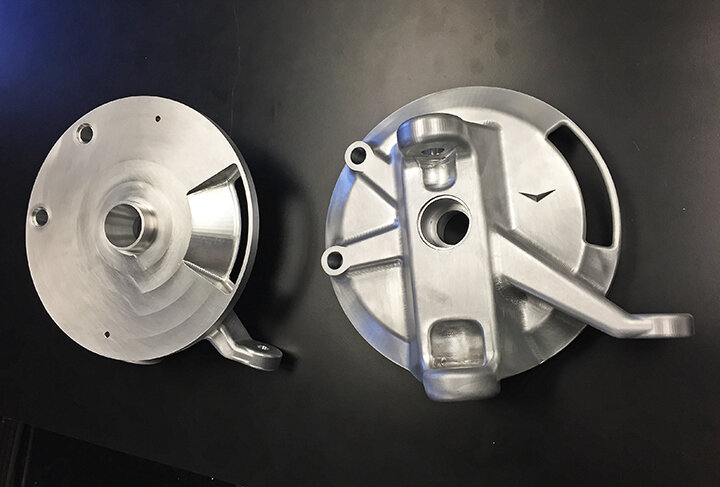

The stainless steel vented front brakes have custom calipers with custom pad covers. In fact, the spindle upright, backing plate, steering arm, caliper mounts, and brake cooling scoops are all machined as one unit.

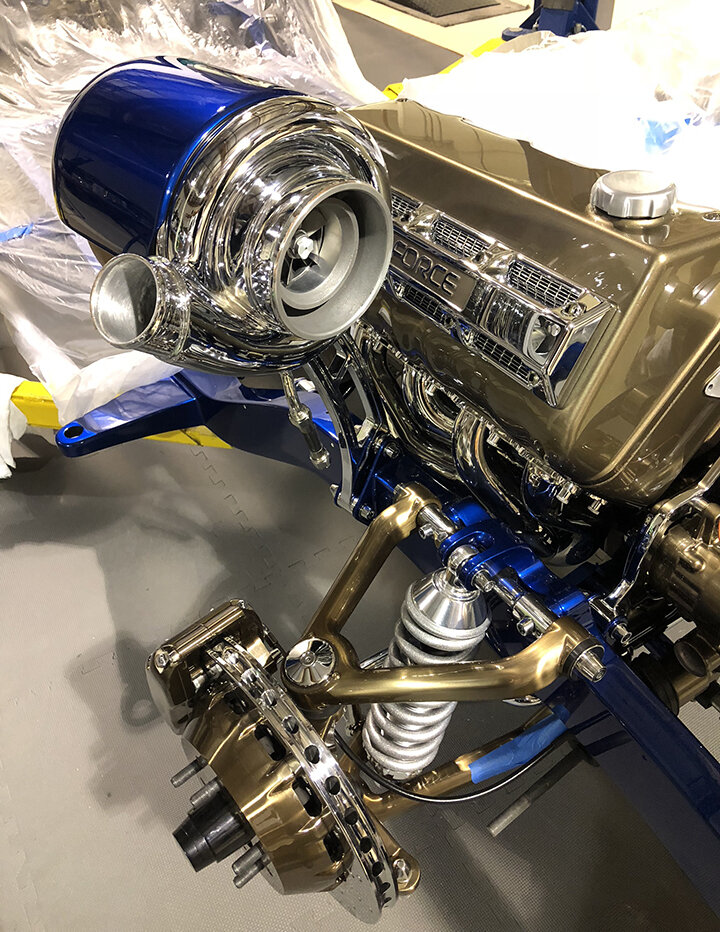

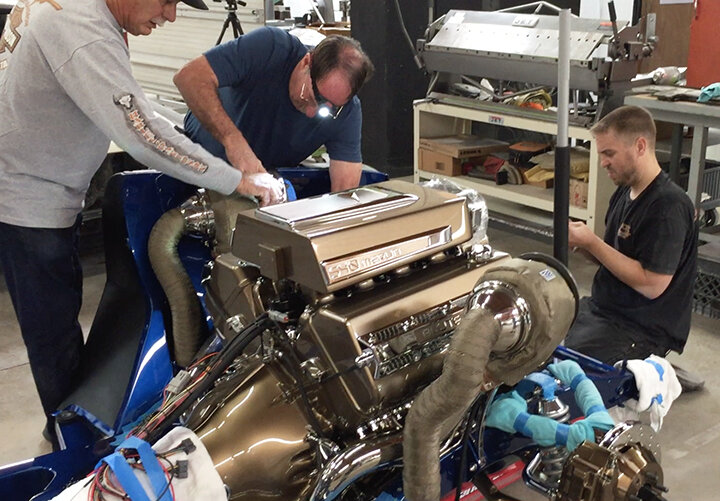

Bob chose a 540-ci Bill Mitchell/World Products Merlin block that was assembled by Mitech Racing Engines, Placentia, CA, with Arias hemi heads. There are twin Garrett turbochargers with Cerakoted housings and chrome plated compressor covers.

What you can’t see most of the time is the assembly on the front of the engine that incorporates a Mezier water pump, an MSD alternator in a custom machined housing, and a power steering reservoir with an internal pump. It’s quite an amazing assembly as is the massaged Hogan intake manifold and the hand-formed plenum assembly. Even the Arias valve covers were filled and ground and fitted with custom coil covers.

The stainless steel headers and exhaust system was all custom built as were the mufflers by Ryan Rivers. The engine compartment is finished in the contemporary style but is not so smooth as to look like a suitcase and retains the look of a real engine.

It’s a shame that most observers will never see what’s under the skin but the skin itself is equally amazing. It’s impossible to list all the features, modifications and details. It’s a truly outstanding piece of artful engineering.

Mick Jenkins of Mick’s Paint, Pomona, CA that handled the body and paint said, “There’s not a panel that we didn’t touch. The roof had to be re-aligned and chopped just ¾-inch while the drip rail was shaved. The front fenders required extensive reworking especially around the headlight area. The reverse-opening aluminum hood had to be split while a new inner frame was fabricated along with new hinges. The corners of the doors were rounded and the handles were shaved. The rear wheel openings were raised and reshaped to accommodate larger tires. The rear fenders were also reworked in order to reverse the angle of the side trim—hand formed by Lil’ Louie—that now leans forward rather than backward as does the ‘sweetheart’ dip behind the door.

“The front and rear windshield frames that that have a subtle peak and no visible attachments were very problematic. Hand formed in brass by Rick Lefever and Bill Brackman, the frames were extremely delicate and required hours of work before they were deemed perfect.

“I think there are around 10,000 hours in the bodywork and at times there were more than 10 people working on the car,” said Mick. “The team included: Anders Berg, Kevin O’Flaherty, Andi Humenik, Rick Lefever, Ivan Perez, Juan Carrillo, ‘Chino’ Sadit Ayallah, Miguel Patino and team leader Poncho Contreras. Paul Hattrup, Bill Brackman and Ryan Rivers performed the majority of the mechanical aspect of the build in Bob’s shop.”

The interior features a steel, wrap-around dash hand-formed by Luc DeLey and fitted with custom gauges crafted by Classic Instruments. Various other trim pieces and covers were formed by Ryan Rivers.

The outstanding upholstery was crafted by Gabe’s Custom Upholstery and is detailed beyond belief and features leather that was sent to Italy for CNC-perforating and stitching before being returned to Gabe’s for assembly.

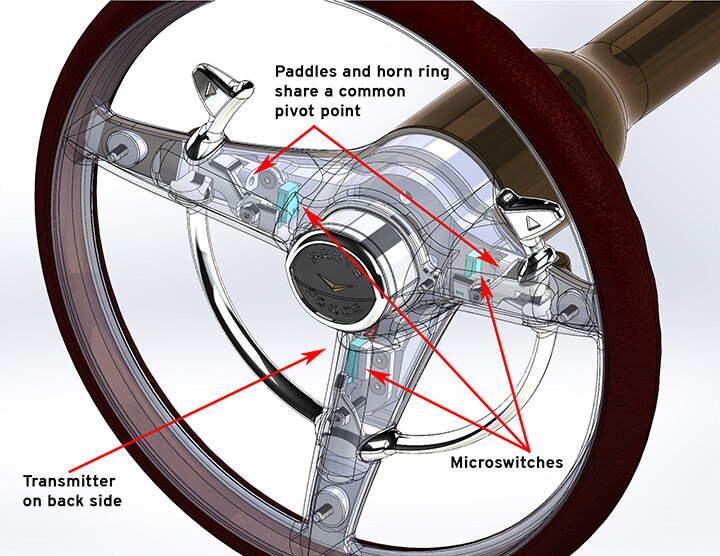

Even the steering wheel is custom made and features integrated shift paddles and horn ring that operate via a radio transmitter.

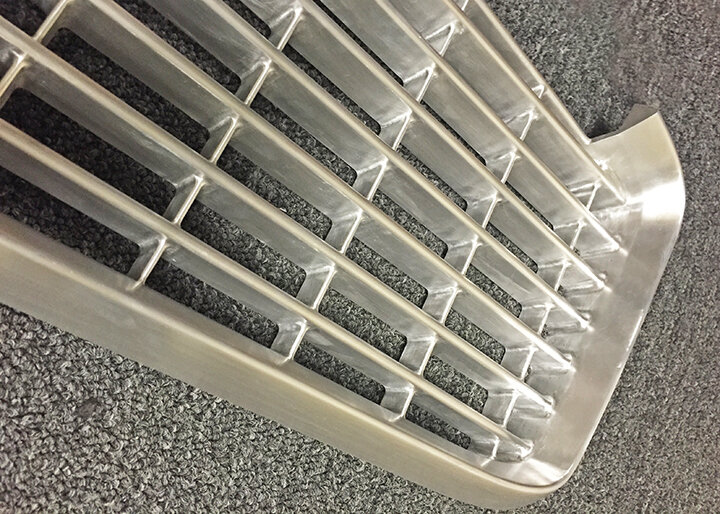

As we said, the list of details is almost endless but we wouldn’t be finished if we didn’t mention that front grille. At first glance, it looks like a factory egg crate but it was machined out of a giant slab of billet aluminum, complete with an integrated V badge before being flawlessly chromed. The grille of our dreams is flanked by equally exquisite billet headlights and ’55 Chevy-style parking lights that are actually downsized 30-percent from stock.

From grille to hand-made bumpers, ‘Brute Force’ is certainly a force to be reckoned with and it will be a while before we see another project detailed to its level.

Vehicle: ’55 Chevy Bel Air ‘Brute Force’

Owner: Bob and Elaine Matranga

Designer: Chris Brown

Powertrain

• Engine: 540 ci World Products Merlin

• Builder: Mike LeFever MitechEngines.com

• Block: BillMitchellProducts.com

• Heads: Arias

• Valve covers: Arias filled and machined smooth

• Plenum: Handmade with custom trim

• Intake: HogansRacingManifolds.com

• Alternator: MSD

• Transmission: 4L80E by Lakeforesttransmissionrepair.com

• Radiator: Mattson’s Custom Radiator

Chassis

• Frame: ArtMorrison.com

• Wheelbase: 115 inches

• Suspension: Kugel Komponents.com IFS/IRS with custom features

• Shocks: QA1

• Rear brake rotors: Jennison

• Steering: Rack-n-pinion

• Column: Flaming River

• Sway bar: Custom with hidden bushings

• Dash: Luc DeLay, Marcel’s Custom Metal

• Instruments: Classic Instruments, iPad control for audio, HVAC and other systems

• Steering wheel: Custom with integrated, radio operated shift paddles and horn ring

• Seats: Based on Chrysler Sebring convertible

• Upholstery: Gabe’s Custom Upholstery

• Paint: PPG

• Paint by: MicksPaint.com

• Color: Custom PPG mix ‘Brute Force Blue’

• Coatings: Cerakote.com

• Plating: QCP Enterprises and Custom Metal Finishing

• Wheels: Custom design 18x7 front, 20x10 rear

• Tires: Pirelli P Zero 215/40ZR18 front, 295/40ZR20 rear