Tech: When Ford Adapter or Block Plates Go Bad and How To Fix ‘Em

September 2020 • Tony ThackerI’d never heard of this situation before until I stopped by Rick ‘Speed’ Lefever’s shop in Pomona, CA, to photograph his son Rayce’s Model A coupe and saw him working on this Ford engine and Tremec five-speed transmission for Carl Akin’s Deuce 3-window. The power train components were assembled elsewhere and said to be ready to be installed and delivered to the customer when Rick decided to perform a fit check just to make sure that everything was correctly installed. Unfortunately, it was far from correct.

Just to be clear, this is not a typical situation; companies such as Holley sell block plates all day long without a problem. However, in this case there were reasons for correcting the existing plate rather than just throwing it away and buying a new one. Here’s how the fix was put in.

The block plate, also known as a separator or spacer plate, is a steel plate that goes between the engine and the bellhousing and is there to ensure perfect alignment between the starter Bendix drive and the flywheel ring gear and the transmission input shaft, the bellhousing and the crank. Perfect alignment ensures that you have the input shaft of the trans aligned with the crank and therefore minimal chance of problems or even an explosion due to misalignment. Most racing organizations require a block plate and they should therefore meet S.F.I. safety requirements if you intend to go racing.

Unfortunately, in this instance none of the components were in alignment consequently Rick had to disassemble the assembly separating the trans from the bellhousing and the bellhousing from the block plate. He was then able to measure the boss, also known as the register, on the trans and the hole in the bellhousing. There’s supposed to be a .005 clearance but in this instance it was .400 or almost ½-inch. Also, the locating hole in the block plate for the starter had been hogged out—why we don’t know—and was no longer locating the starter, as it should. To be blunt, it was a mess and required a complete rebuild.

The gold iridited plate surrounding the ring gear and behind the pressure plate is the block plate used to perfectly align the starter and transmission components. Block plates are available from Holley.

The block plate is supposed to be complete and not have that large half moon-shaped hole at the top and the hole around the starter boss should also be complete and not elliptical.

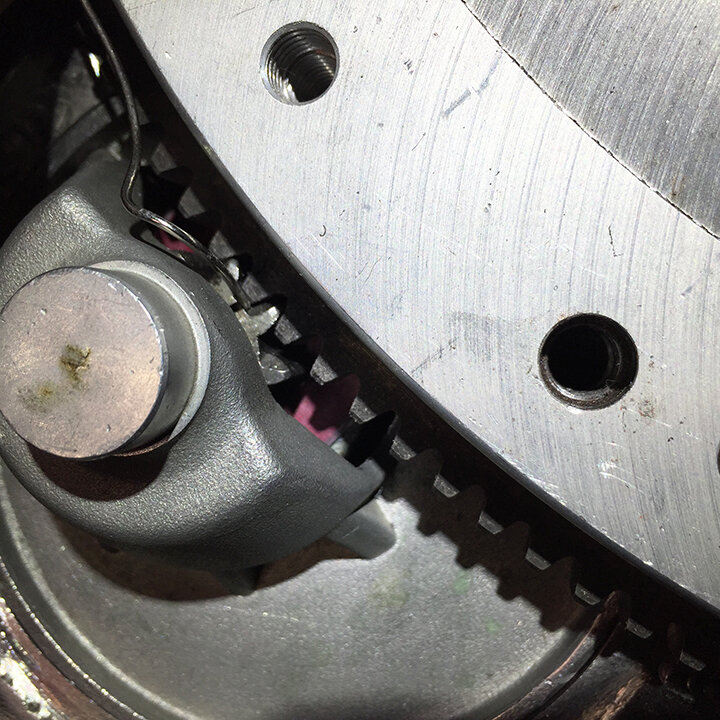

This is a close up of the starter bolted to the block plate. Note that the hole in the block plate, that should be a register for the starter, has been enlarged—wrong.

The hole in the bellhousing is supposed to be a snug fit on the register boss of the transmission with only a .005 clearance.

In this case, the register boss on the Tremec was .400, almost ½-inch smaller than the hole in the bellhousing enabling the trans to walk about. It’s supposed to be .005.

Rick repaired the block plate by filling in the half-moon-shaped hole and replacing the material cut from around the starter hole.

The engagement between the starter Bendix and the ring gear is supposed to be .040 and some careful alignment of the starter is critical. The right size wire acts as a gauge.

Once the block plate had been repaired it was installed on the block after which the flywheel was bolted in place. A dial indicator was then placed on the face of the flywheel.

Next step was to install the bell housing after which the engine was turned over and readings taken of the position of the hole in the bell housing. It was found to be .003 off set.

Because the register boss on the Tremec was .4-inches too small Rick machined up a spacer to take up the slack.

Here, viewed from inside the bellhousing, the spacer ring has been tacked into the bellhousing.

The bellhousing was then machined to the correct .005 tolerance for the transmission register boss. Note that the surface of the bell housing had been machined to make it perfectly square to the block plate.

The bellhousing, complete with spacer ring, mocked into position so that it can be measured again.

Despite all his careful machining, Rick found the trans was still .001 off-set and therefore ordered a set of off-set dowels to move the block plate over .0005.

You might think this operation was way over the top, and you’d be right, but if you’re serious about your build, especially if you are using a Ford engine, and intend to do any racing you’d best be aware of the right way to do it.