Bob Matranga’s 800 hp, 540 ci, Twin-Turbo Merlin, ’55 Chevy ‘Brute Force’ Part 1: The Build

September 2020 • By Tony Thacker, photos Nestor Cabrera • Poncho Contreras, Tony Thacker and Eric Geisert and Scott Council courtesy Bob MatrangaA race is one thing, there’s usually a clear winner, but in the show car world things are not quite so clear-cut. There’s a lot of subjectivity involved, a lot of passion and a lot of judging. And judging by the 2020 Detroit Autorama, a lot of controversy. Take, for example, Bob Matranga’s truly amazingly detailed ’55 Chevy ‘Brute Force’ that didn’t win.

Bob Matranga, the man behind ‘Brute Force.’

Bob’s a consummate car guy and has a garage full of rad rides, from sports cars of the fifties to several Hot Rods By Boyd. Mostly though, there are muscle cars, but Bob said, “I like to build hot rods. That’s driven me all my life.”

TorqTalk was lucky enough to follow a significant part of the build as well as the body and paint while the car was at Mick Jenkin’s MicksPaint.com, Pomona, CA.

The original concept for what became known as ‘Brute Force’ was penned and managed by designer Chris Brown who said: “When you’re trying to create something that has a lot of hand-made components it’s hard to make it perfect and it’s that challenge that makes these cars so special. We tried to push the envelope with this car.”

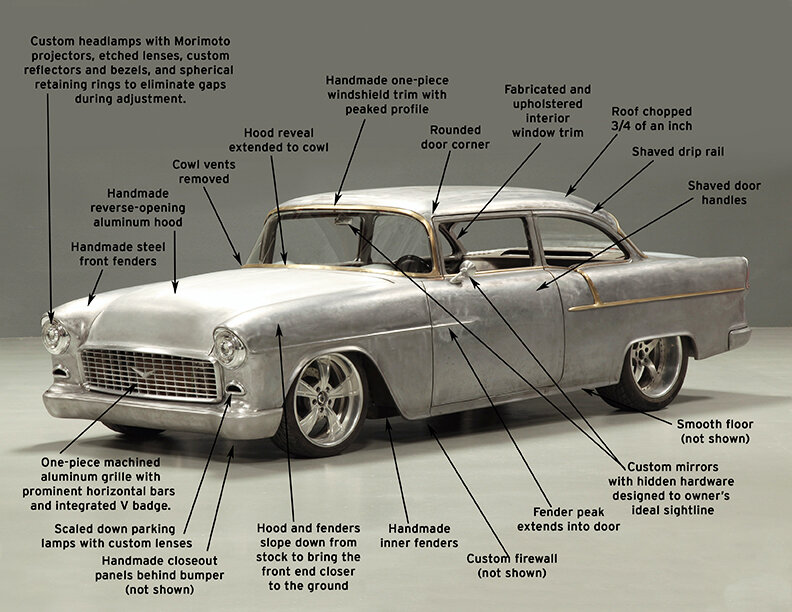

Unfortunately, as some projects do, it went awry in the early stages when a shop that shall remain nameless drooped the front fenders unevenly and chopped the top but cockeyed the other way. It was enough to make any man cry but not Bob; Bob has tenacity and stuck with what turned out to be a 10-year build. “When Bob came to us,” said Mick Jenkins, “we talked about starting over but as Bob said, ‘We managed to save it.’” Even given the space we can devote to this car, it’s impossible to list all the features, modifications and details. It’s a truly outstanding piece of artful engineering.

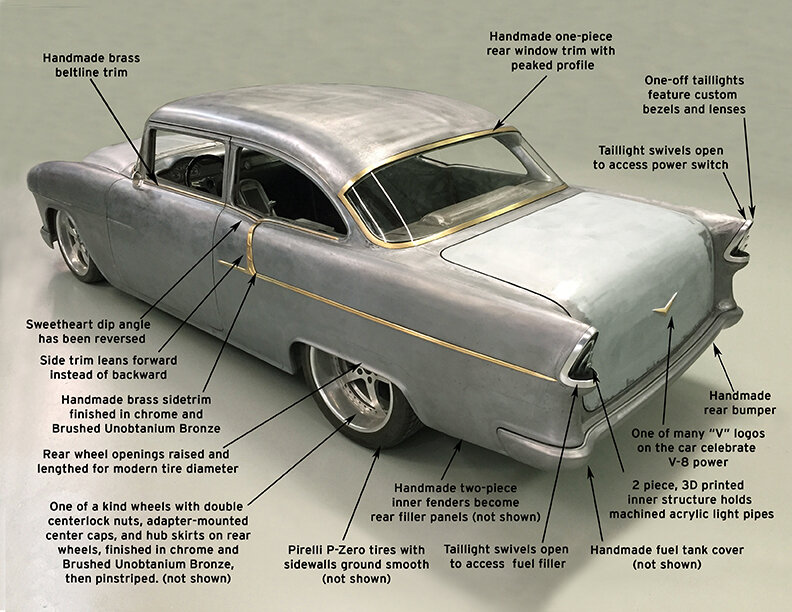

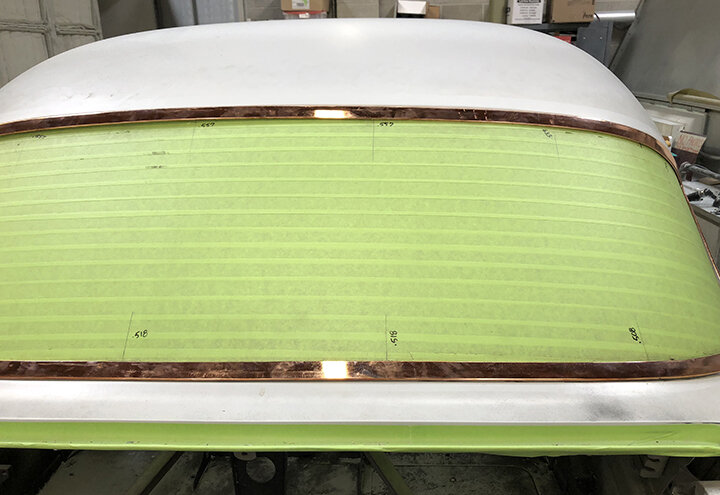

Jenkins went on to say: “I don’t think there’s a body panel that we didn’t lay hands on. For example, the roof, which is chopped a mere ¾-inch, had to come off to be re-aligned and have the drip rail shaved. The front fenders needed extensive reworking especially around the headlight area. The aluminum hood had to be split and a new inner frame fabricated along with new hinges. Likewise the decklid needed a new inner structure. One door in particular required a lot of work to extend the fender peak and we also shaved the handles. The rear wheel openings had to be removed, reshaped and raised to accommodate larger tires. The rear fenders were reworked in order to reverse the angle of the side trim—hand formed by Lil’ Louie—that now leans forward rather than backward as does the ‘sweetheart’ dip behind the door.

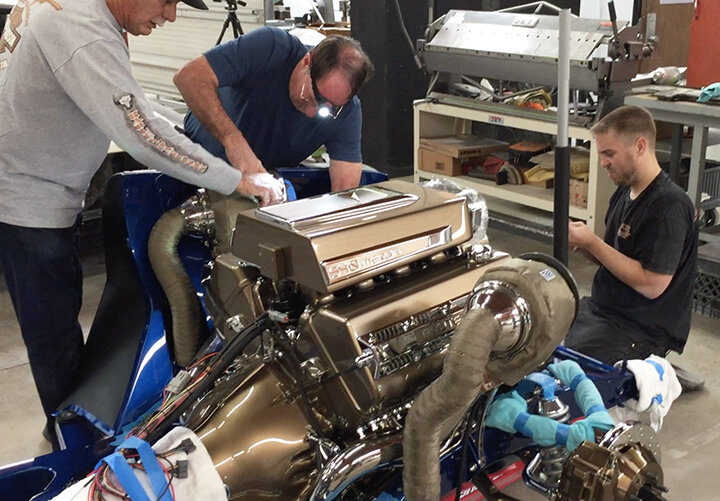

“Beyond the body and paint, the build process was extremely complicated. For example, we had to completely re-engineer the hood hinges made by the previous shop. Paul Rivera had to design and fabricate body mounts at the firewall as well as reinforce the firewall while Andi Humenik modified the intercoolers to better fit around the hood hinges.”

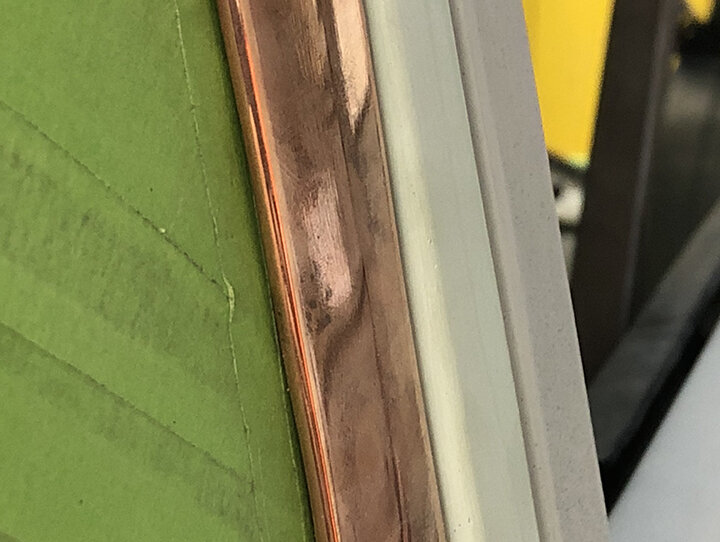

“One area that really was a problem was the handcrafted front and rear windshield frames that had a subtle peak and no visible fasteners. They would go to be plated and the heat generated during the polishing would warp the trim ever so slightly. They’d come back and they wouldn’t fit. I think those frames by Rick Lefever and Bill Brakman were plated 10 times before they were correct. It was a long frustrating process. Similarly, all the lights are hand made, as are the front and rear bumpers.”

“We also put in a huge amount of time and effort into painting all the small parts: Everything from the block and its ancillaries, to the transmission and the rear end are all painted in PPG Toyota Bronze Amber. There was also myriad other parts from the frame up through the turbo covers, to the custom dash by Luc DeLey and various trim covers formed by Ryan Rivers—it all had to be painted.

“I think we put around 10,000 hours into the body and paint and at times there were more than 10 people working on the car.” Mick’s’ team included: Anders Berg, Kevin O’Flaherty, Andi Humenik, Rick Lefever, Pauly Rivera, Ivan Perez, El Rojo, Juan Carrillo, ‘Chino’ Saidt Ayalah, Miguel Patino and team leader Poncho Contreras. Paul Hattrup, Bill Brackman and Ryan Rivers performed the majority of the mechanical aspect of the build in Bob’s shop.

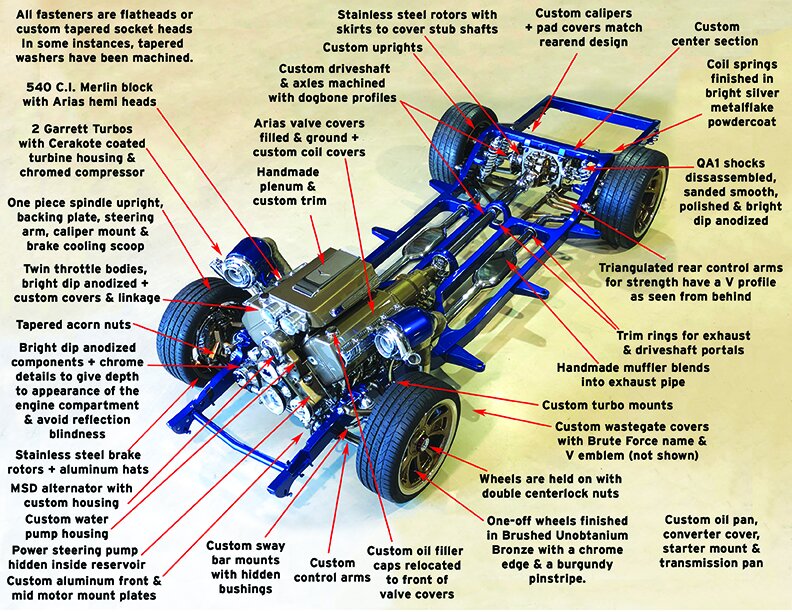

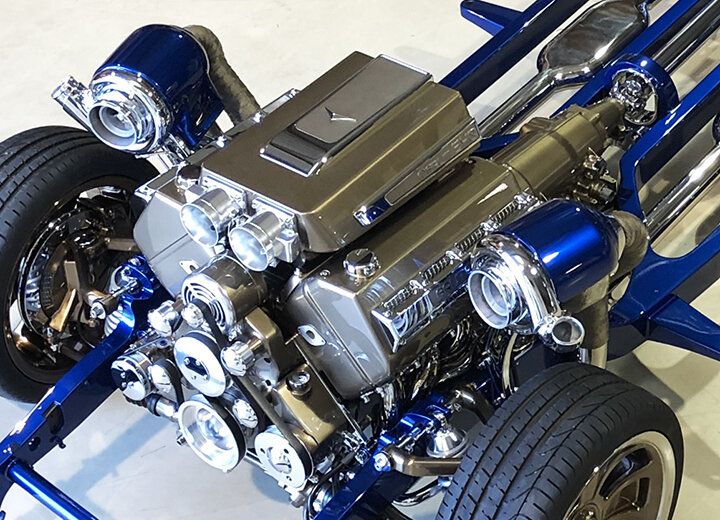

Underpinning the remarkable body resides an Art Morrison fame that was four-cornered with independent suspension from Kugel Komponents. The six coil-over shocks are from QA1 while the brake rotors and drive shafts are from Jennison Engineering. The stainless steel vented front brakes have custom calipers with custom pad covers. In fact, the spindle upright, backing plate, steering arm, caliper mounts and brake cooling scoops are all machined as one unit.

For power Bob chose a 540 ci Bill Mitchell/World Products Merlin block that was assembled by Mitech Racing Engines, Placentia, CA, with Arias hemi heads and a one-off Hogan intake. There are twin Garrett turbochargers with Cerakoted housings and chrome plated compressor covers that feed twin throttle bodies mounted to the front of a hand-made plenum with custom trim. The stainless steel headers and exhaust system was all custom built as were the mufflers by Ryan Rivers.

Unfortunately, and probably for political reasons because it certainly can’t be for attention to detail and finish, ‘Brute Force’ did not win at Detroit—but that’s show business, one can’t fault the car.

Part II: The feature to follow.

Vehicle: ’55 Chevy Bel Air ‘Brute Force’

Owner: Bob and Elaine Matranga

Designer: Chris Brown

Powertrain

• Engine: 540 ci Merlin

• Builder: Mike LeFever MitechEngines.com

• Block: BillMitchellProducts.com

• Heads: Arias

• Valve covers: Arias filled and machined smooth

• Plenum: Handmade with custom trim

• Intake: HogansRacingManifolds.com

• Alternator: MSD

• Transmission: 4L80E by Lakeforesttransmissionrepair.com

• Radiator: Mattson’s Custom Radiator

Chassis

• Frame: ArtMorrison.com

• Wheelbase: 115 inches

• Suspension: KugelKomponents.com IFS/IRS with custom features

• Shocks: QA1

• Rear brake rotors: Jennison

• Steering: Rack-n-pinion

• Column: Flaming River

• Sway bar: Custom with hidden bushings

• Upholstery: Gabe’s Custom Upholstery

• Paint by: MicksPaint.com

• Color: Custom PPG mix ‘Brute Force Blue’

• Coatings: Cerakote.com

• Plating: QCP Enterprises and Custom Metal Finishing

• Wheels: Custom design 18x7 front, 20x10 rear

• Tires: Pirelli P Zero 215/40ZR18 front, 295/40ZR20 rear